Plastic Components Plant implements chemical hazard response drill

On Oct. 28, THACO INDUSTRIES Safety Management Department and THACO Chu Lai Health Department organized a chemical hazard response drill for nearly 300 employees at Plastic Components Plant. The annual activity aims to raise awareness and improve coordination in handling chemical incidents.

The drill involved two scenarios. In Scenario 1, a large LPG gas leak occurred at the Plastic Components Plant's Backup Area due to a faulty gas pipe joint, posing a suffocation hazard in enclosed spaces. At the time, 115 employees were working in the factory and needed to evacuate safely. One employee sustained frostbite, and another was suffocated.

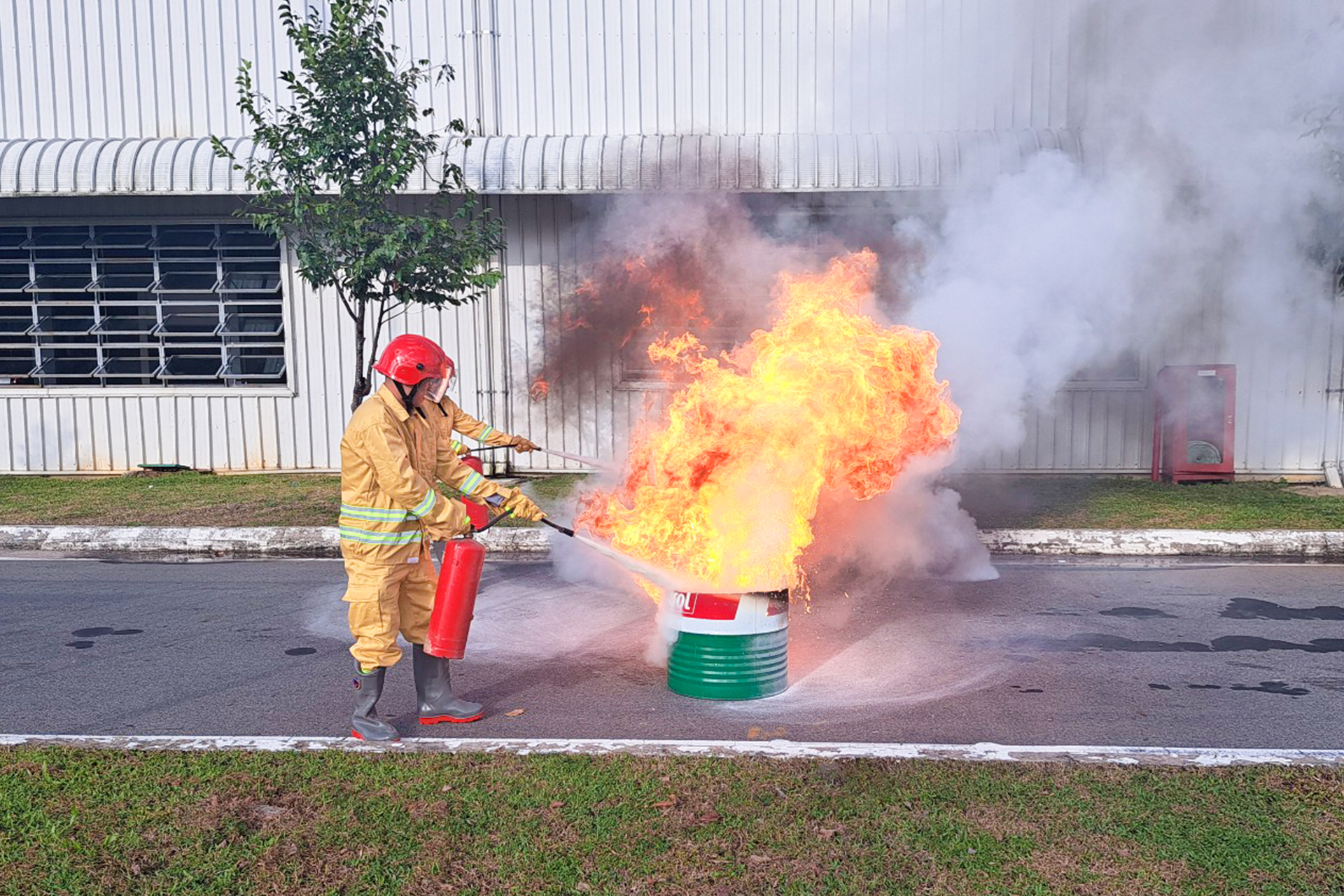

In Scenario 2, an LPG gas leak at the Backup Area ignited a fire, releasing toxic fumes and posing a risk of spreading to nearby areas. At the time, 115 employees were working in the factory and required evacuation instructions. 113 employees were trapped inside, one employee suffered frostbite, and another was suffocated due to exposure to LPG gas and the fumes generated by the fire.

Upon detection, designated units sprang into action, mobilizing resources through alarms, phone calls, reports, and dispatching personnel and vehicles to the site. Response measures were swiftly implemented, including power cutoff, gas valve shutdown, chemical identification and leak isolation, evacuation guidance, first aid for casualties, using natural ventilation, compressed air or fire extinguishing system deployment to dilute and disperse LPG gas in case of a leak, and put out fire, moving supplies to a secure location in scenario 2.

|

|

|

|

The drill reinforces, expands, and refines the participants' knowledge in chemical incident response, thereby enhancing worker safety, safeguarding assets, and maintaining production and business stability.